Reloading: Thoughts on Finding the Perfect Load and Volume Production

November 29, 2020

Civilian Marksmanship Program▸The First Shot▸Reloading: Thoughts on Finding the Perfect Load and Volume ProductionBy Danny Arnold, Team CMP Highpower

If you’ve seen Team CMP at a match, you might have wondered if the team is shooting issued ammunition or if we load our own. The truth is, if you see several team members at an event, the ammunition that we fire at the 200- and 300-yard lines is “Team” ammunition purchased from a vendor for that shooting season. The ammunition that we fire at 600 yards is each team member’s personal load, and each of those rounds is loaded by us.

Being furnished ammunition is a nice perk, but I should point out that we only shoot “Team” ammunition when we’re all together at an event. The rest of the time, we’re shooting ammunition that we load ourselves. That adds up to a lot of ammunition each year: In my case, another 2,000 to 3,000 rounds, assuming a “normal” year, i.e., not 2020.

In this article, I’ll provide some thoughts about finding a good 200- and 300-yard load and how to efficiently produce a lot of it, since 75 percent of our shooting is done at those yard lines.

First, a thought on what constitutes a good load: This comes from fellow teammate Bob Gill who put into words something that I had suspected for a long time. In a conversation about choosing the team’s ammunition for the 2021 season, Bob commented that a proven load will shoot good groups if shot through a quality upper, regardless of bullet manufacturer or powder. That flies in the face of the “Perfect load for a particular barrel,” school of thought, but it’s easy enough to check out.

The members of Team CMP are using barrels from different manufacturers with different chamber configurations, yet the team ammo shoots winning scores on the road. At home, individual team members are producing their own ammunition using different bullet and powder combinations that we independently selected, and those combinations also produce winning scores. That lends credence to Bob’s statement, but I thought I’d put it to the test.

My testing procedure was simple: At 200 yards, slung up in the prone position, I’d fire a total of 12 slow-fire shots from the magazine without breaking position. The first two shots would be fouling shots fired off the target and the next ten would be directed at the X-ring of the SR 200-yard target. The ammunition would be my own hand loads, “Team” ammunition and a box of factory-loaded “Match” ammunition from a different manufacturer that I had won somewhere as a door prize. All of the ammunition was loaded with 77-grain bullets. Both my bullet and powder was different than the “Team” ammunition, but the bullet from the “Team” ammunition was the same brand as the “Match” door prize ammunition.

The results: five to six shots in a tight group with the remainder hovering close by. No load resulted in a group larger than the X-ring, which spans 1.5 MOA at 200 yards. Keep in mind that those were 10-shot groups.

The takeaway here is that finding a good 200- and 300-yard load for your service rifle shouldn’t be an excruciating process. If you’re using a bullet and powder that other competitors are using, you should be able to find a load that your rifle likes.

Once I decide on a bullet, a powder that meters reliably through my powder measure, a primer and a desired velocity range, I load 10 rounds of each test load, increasing in .2 (2/10) grain increments. Depending on the powder, this may result in seven or eight different loads. I test each load at 200 yards from the prone position by loading all 10 cartridges in the magazine and slow-firing them without breaking position. In most cases, groups start decreasing in size as the charge increases, then as signs of pressure increase, group size increases.

Occasionally, groups may decrease in size once again as pressures run toward the high side. However, I’ll say it here: I’m not a fan of hot loads. I shoot in temperatures ranging from the low 40’s to over 100 in East Texas. No matter how well a hot load shoots, a primer lodged in your trigger group will cost you the match.

Ideally, I want to see two loads that are .2 (2/10) of a grain apart that shoot almost identical, accurate groups.

Why, you ask? Because, the second part of this process is making a lot of ammunition as quickly and easily as possible.

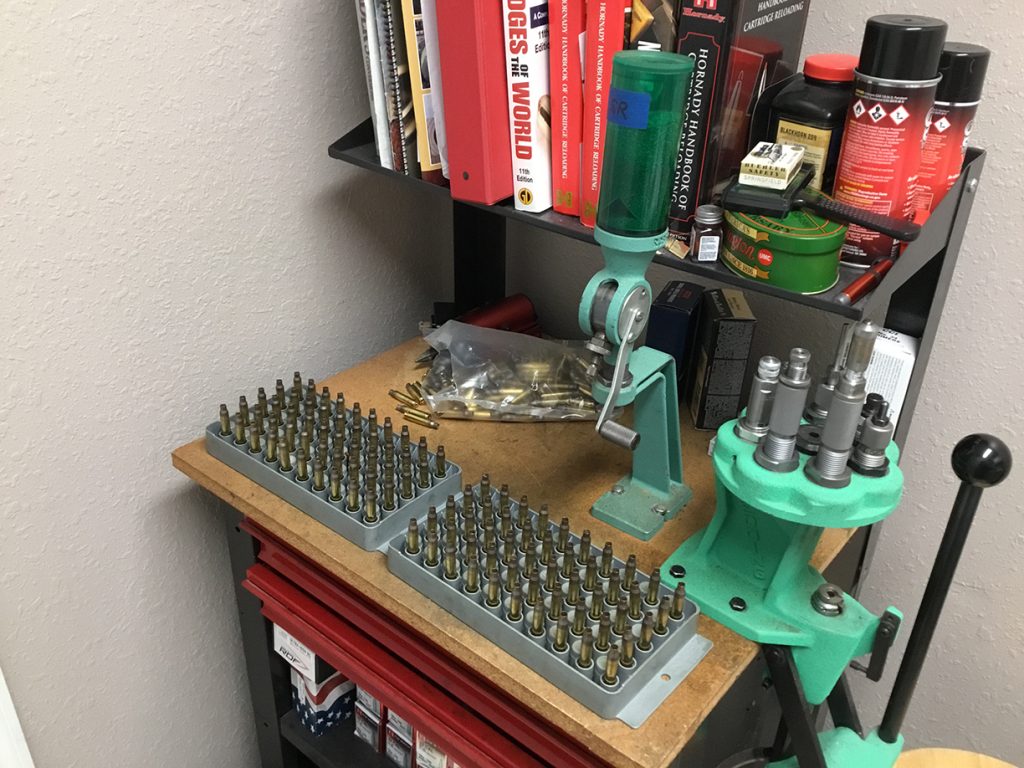

All of my reloading equipment is from solid, well-regarded manufacturers, but none of it is expensive. Some of it is over 20 years old at this point. My reloading equipment for Highpower consists of a hand-operated primer seater, a seven-hole turret press, four 50-round loading blocks, a funnel, two powder measures with baffles, a scale that measures to .01 (1/100) grain, a set of RCBS X-Dies for sizing and seating 200- and 300-yard ammunition and a set of match grade sizing and seating dies with a micrometer seating stem for 600-yard ammunition.

All of the dies (a total of four) stay screwed into the turret press so that I never have to do anything other than clean them occasionally. Notice that a progressive-style press isn’t on my reloading bench.

The X-Die is designed to limit case stretching when the neck is sized and eliminates the need for case trimming, which cuts a step out of the brass preparation process. The downside is that the die works the neck of the case more than a standard sizing die. I view it as a trade off: I’m probably shortening my brass life by a reloading cycle or two, but I’m also saving time that can be used elsewhere.

The load that I choose will fall in between the two best shooting loads that I tested. Remember, I want two loads that fall .2 (2/10) of a grain apart. If the first load is XX.4 grains and the second is XX.6 grains, I’ll set my powder measure to throw charges of XX.5 grains. That way, if a charge is .1 (1/10) of a grain off either way, it should still shoot well. Even if a charge is off by .2 (2/10) of a grain, it’s still okay. That round might be shot in standing. Or, maybe it’s the high or low “10” in my rapid-fire group. Regardless, I don’t worry about it.

There is a caveat here: If I pull the charging handle and there is a hesitation, or worse yet, it momentarily hangs up because it’s cutting the powder, I dump that charge back in the hopper and start over. From experience, I know that charge is going to be off by more than .2 (2/10) of a grain.

My reloading process is straightforward: Starting with 1,000 rounds of new brass, I prime 200 with the hand primer and put them in the loading blocks, drop powder in all of the cases, visually inspect for high or low powder levels, set bullets atop the case necks and then seat all 200, one right after the other. Loaded rounds go into a Ziploc freezer bag with the date written on the side with a sharpie, along with the number of times loaded.

Then, I take a break, maybe for the rest of the day. Approaching reloading in production line style allows me to load 200 rounds in an hour when I start with either new or sized and clean brass. That’s not as fast as the claimed speeds with a progressive press, but it’s pretty close, and I can easily check the entire process as it’s being done. Over the course of a few days, 1,000 rounds get loaded pretty easily.

I don’t size any brass until I have at least three matches worth. For me, it’s just not worth the time to size 60-odd rounds. Working in 200-round increments is about right with this system: More than that exceeds my tedium threshold – less, and I wonder why I bothered getting my hands dirty. That also sets me up to load another 200 rounds once I get the brass out of the tumbler.

I like to shoot, but I don’t really enjoy experimenting or loading ammunition. It’s one of the necessary evils of competitive shooting that ranks somewhere between teeth cleaning and colonoscopies in enjoyment. As a result, once I find a load that works well, I tend to stay with it for a long time. Having lots of ammunition around the house and knowing that you can make more of it with less hassle means more time to practice.

More practice = Better scores.

I appreciate your information and I’m getting set up for reloading, but like you have a limited area in the house. Your “bench” may be just the ticket for my situation. Can you share the manufacture and where it was obtained?

Also, for your 77 gr reloads, can you share the specific bullet you are using?

Lastly, do you happen to know what 77 gr bullet is being used for the supplied manufactured ammo?

Thanks and stay safe and well

John,

That bench, like a lot of my equipment is 25 years old now. I know how long it’s been because my reloading area was condensed and moved into the laundry room when my son was born. It’s stayed there ever since.

I searched the internet in the off chance that somebody still made that bench, but couldn’t find anything. I will say that it doesn’t feel very sturdy until you stack about 200 pounds of bullets and loaded ammunition in the lower part of it. In my search, I did see a few workbenches that looked like they would be suitable, so it’s just a matter of seeing what looks like it will work for you. Remember that every tool you own doesn’t have to be permanently mounted on the bench. I’ve got a hand operated neck trimmer (for oddball calibers and hunting ammunition) and a separate neck turning tool that stay in their boxes until needed. The mounting holes are drilled in the bench top and all I need to do is insert screws and tighten everything down when I need to use those tools.

As for 77 grain bullets…

I’ve used Noslers and Sierras with success over the years. Unfortunately, right now, it’s more a matter of what you can find.

I’m not sure what bullet the team ammunition is loaded with for the 2021 season. We’ll be shooting the Orange Blossum Regional followed by the Talladega Spring Classic in March, so we’ll see how it performs in just a few days.

Danny

Good article Danny,especially the part about in between powder charge of 2 good groups.

Excellent article. I’ve been shooting for some 45+ years and this is definitely one of the best reloading articles I’ve read. I’ve been shooting Sierra MatchKing’s 69gr HPBT for the past several years with good results out of my Colt HBAR. Just started working up loads for 77gr hoping for some improvements with the heavier bullet.

Danny Great article. Would you be interested in sharing the 600 yard load process

Jace,

I’m planning to do something on the 600 loading process in the future.

Danny

Good article …

Well written/concise article from an accomplished shooter. Too many competitors get caught up in finding the “perfect load”. I’ve seen many shooters keep searching for that magical 1/2moa load when they can barely hold 2moa with their rifle. This ain’t BR. Find a load that works AND GO SHOOT!

Great article Danny!

Match loadings all on new brass? Why not processed military lake city brass?

How many firings do you get from your new brass?

Dan,

All new brass or once-fired and processed Lake City doesn’t really make any difference. I’ve used both. However, all of my short range brass has been Lake City for years.

Thé brass I was using for the photos was some brand new contract overrun Lake City brass that I picked up a couple of years ago and had sitting in the closet.

As to brass life, I usually discover a few split necks during the sizing or seating process at about the fifth reloading. That number goes up as the brass is sized.

I have reloaded short range brass up to 10 times, although I relegate it to practice sessions. I haven’t experienced any head separations, just neck splits. That could be affected by how much you size the brass, I.e. how much you move the shoulder back and how many different chambers you’re firing the brass through.

Hi Danny-

77’s with which powder and how many grains?

I’ve been using N-135 with 69 gr HPBT’s and has worked really well for years.

Thanks-

Joe McBride

Joe,

I’d prefer to stay away from giving out load information. There’s way too many chamber configurations and other factors that can effect the safety and success of any load.

If you’re looking to change bullets, I’d suggest checking the load data provided by that manufacturer and compare it to other manufacturers load data for the same bullet weight. That usually provides a starting point for experimentation.

Danny

One of the best reloading articles I ever read. I wonder if you remember Infantry trophy match when bullet s trimed to fit magazine. I was honored to work in the pits but treated like a team member

Ron,

I remember that day very well!

I hope I never need a multi-tool to go down range again.

Danny

you said you load 77 grain bullets ????? ,,, or is that 177 grain bullets ,,,, where can i purchase some of these ???? ,,, and can you provide a good starting load for compitition shooting at 200 – 300 yards ,,, i liked the article veary much ,,, veary helpful ,,, thank you bob 🙂 ,,,

77 grain HPBT are for .223/5.56

Robert,

Yes, the article is correct.

I, as well as the rest of the CMP Team shoot AR15 Service Rifles for the across the course matches. For the 200 and 300-yard stages, I use 77-grain bullets. For 600 yards, I use 80 or 85-grain bullets.

When I shoot GSM (M1 Garand) or Vintage Sniper (M1D) matches, I use 155 or 168-grain bullets.

Finding ANY reloading components is hit or miss at the moment. When any come up for sale, they’re typically gone within minutes thanks to the ease of purchasing on line.

I hesitate to share load data due to the differences in individual rifles, so I would recommend consulting any of the available reloading manuals. Hornady, in particular has an entire section devoted to reloading the M1 Garand if that’s your choice of rifles.

The article was geared toward Across the Course shooters due to the number of rounds fired over the course of a season. However, GSM competitors can use the same techniques. Producing large quantities of accurate ammunition is largely a matter of sequencing the reloading steps for efficiency.

Good Shooting!

Danny